As an international manufacturer of building acoustic equipment Ntek has its own laboratory to calibrate tapping machines and sound sources. Ntek calibration laboratory works on all brands and models of equipment, offering a fast and accurate service.

As foreseen by the ISO 16283-1/2/3 standard, it is recommended to perform the revision of sound sources (dodecahedron, directional speakers, tapping machines) every 2 years. We also recommend annual calibration of the products after the purchase.

The calibration provides documented and traceable measurement accuracy and confirms that your product meets the published specifications.

TAPPING MACHINE

Verification of the impact velocity, impact rate and the dimensional measurements of the hammers according to UNI EN ISO 16283-2 and UNI EN ISO 10140 – Annex E – using the following instruments:

– test bench with structure in aluminum and serizzo marble surface;

– laser velocimeter

– a caliber and a precision scale interfaced with an industrial computer with specific post-processing software.

We’d like to highlight that all the measurements are made with our test bench don’t need to open the equipment (that could cause the voidance of the warranty).

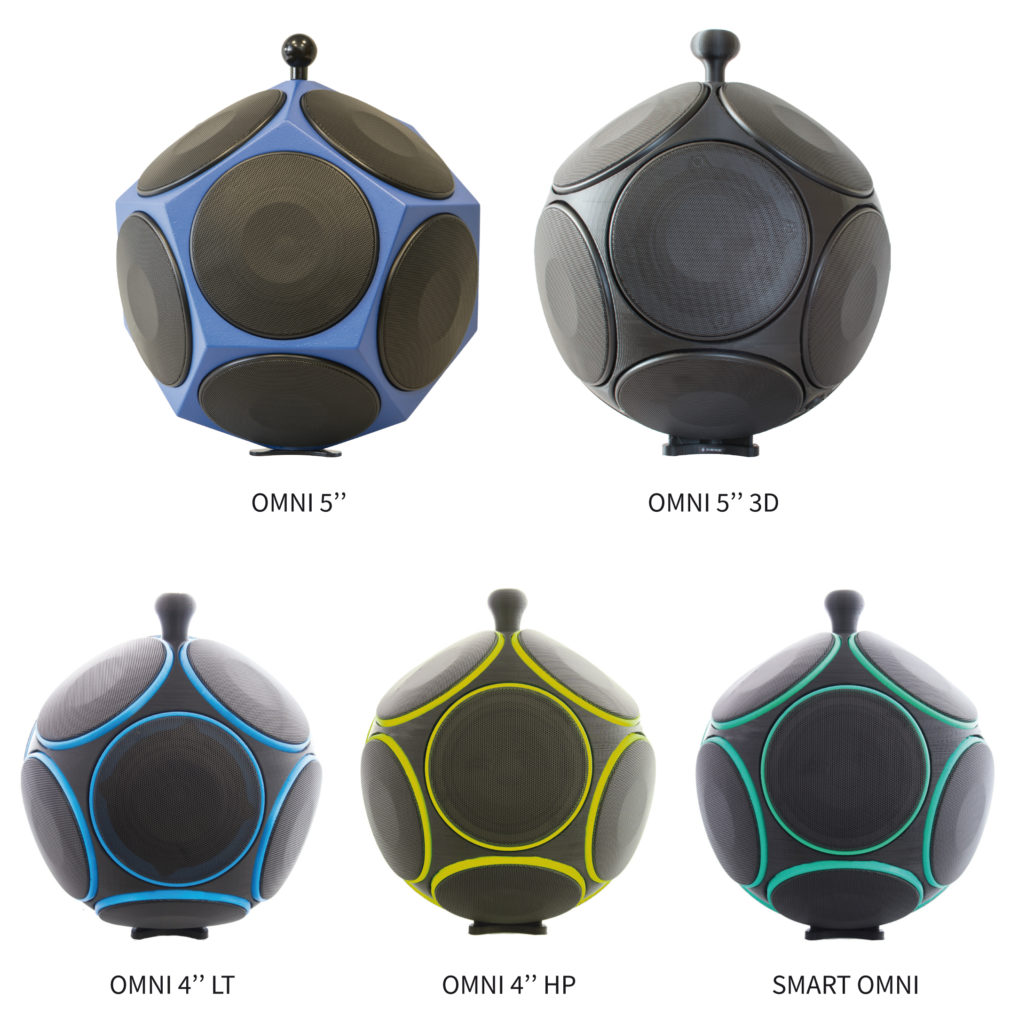

SOUND SOURCES

UNI EN ISO 16283-1 standard also require bi-annual verification of the speaker systems to confirm compliance with this standard. Verification of dodecahedron loudspeaker directivity in accordance with ISO 16283-1, Annex A. Requires matched power amplifier.

Ntek calibration laboratory has developed a verification procedure to comply with these requirements: the dodecahedron speaker is assembled on a rotating engine in a semi-anechoic chamber through 360° and measured by several microphones in order to obtain the omnidirectionality. Measurements are calculated and compared with the specifications.

COME AND MEET US IN OUR LABORATORY!