Labtone

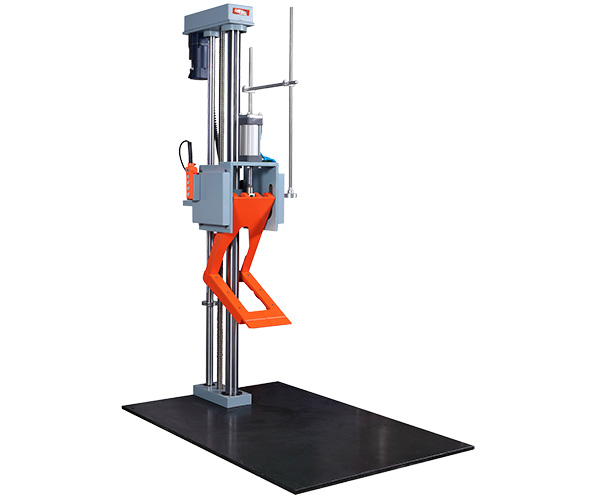

Standard drop test

The standard drop test system is used to determine the effect of impacts on packaging during loading, transport, unloading, and subsequent use. In addition to accurate planar drop tests, the system can also conduct corner or edge drop tests, performing a comprehensive assessment of packaging and product performance.

FEATURES

- Meets international standards such as GB, IEC, ASTM, ISTA, and other industry standards.

- It performs surface, corner, and edge drop tests.

- Pneumatically operated precise steering system.

- Unique swing arm design with a release acceleration greater than 3G.

- Double column guide, a hydraulic damper absorbs the retraction force of the swing arm, thus achieving stable, reliable, and silent movement.

- Self-locking screw in the lifting mechanism to avoid abnormal detachment of the swing arm.

- Extensible support bracket and lower base included.

| Model | DT150 | DT200 |

|---|---|---|

| Drop height (mm) | 300 – 1500 | 300 – 2000 |

| Max payload (Kg) | 85 | |

| Package size (mm) | 800 x 800 | |

| Drop mode | Free fall drop | |

| Machine size (mm) | 1000 x 1500 x 2100 | 1200 x 1700 x 2600 |

| Machine weight (Kg) | 480 | 550 |

| Power supply | 220V 50Hz – Compressed air: 0.5 – 0.7 MPa | |

| Standards | ISO2248-72(E) GB/T4857.5 JISZ0202-87 IEC68-2-27 ASTM D5276 | |